Products Introduction

Products Introduction

Product introduction and technical parameters

1. Energy-saving mechanism of products

When the furnace is heated, the heat generated by fuel combustion is transferred to the heated object in the form of convection and radiation. When the temperature is lower than 700°C, the heat transfer is mainly convection; when the temperature is higher than 700°C, the heat transfer is mainly radiation. And at 1500'C, when the peak wave peaks, it starts to fall again, when it peaks at 2000°C, and so on. The heat transfer in the high temperature zone of the furnace is mainly radiation, and the radiation heat transfer at high temperature accounts for about 90-95% of the comprehensive heat transfer. Because the size of the radiation energy is proportional to the fourth power of the absolute temperature, and the radiation energy is transmitted outward in the form of far infrared wave, when the heat radiation emitted by the coating surface falls on the workpiece and fuel. When on, it is absorbed by the workpiece and fuel. These infrared waves are extremely penetrating and can penetrate both the heated workpiece and the fuel itself, heating both the heated workpiece and the inner and outer layers of the fuel. When penetrating the workpiece and the inner layer of the fuel, the molecules of the workpiece and the inner layer of the fuel absorb the far infrared wave and produce the energy level transition, which makes the fuel burn more fully, releases energy to accelerate the heating and combustion, changes the heating and combustion conditions, reduces the incomplete combustion loss of the fuel, makes the central temperature of the heated object and the surface temperature basically the same, and shorens the heating time. It is 20°C lower than the original rolling temperature, so as to achieve the purpose of energy saving.

2. Product introduction

High temperature far-infrared insulating energy-saving coating and other products, safety, environmental protection, non-toxic and harmless, has the following advantages: (1) high temperature resistance, the highest use temperature of 2000°C. (2) can be directly sprayed on refractory materials or insulation materials, easy construction. (3) Wide range of applications. (4) Long service life. (5) The cost is lower than the commonly used radiator and heating element.

Under the premise of not changing the material, quality and surface area of the refractory in the furnace, when the surface of the refractory inside the furnace is sprayed with high temperature far-infrared insulating energy-saving coating, after high temperature sintering, the coating penetrates into the inner layer of the refractory about 2-5mm thick depth, the surface glaze spreading is good, no glaze drops, solid bonding, Wear resistance, air erosion resistance, good air tightness, small thermal conductivity, thermal shock resistance, good slag resistance, corrosion resistance bright hard ceramic body, strong thermal radiation, high blackness, improve the furnace temperature 60-100C, furnace surface temperature reduce 5-20°C, reduce the furnace slag scale 30-50%, reduce the oxidation sheet 20-80%, reduce smoke about 45%, Energy saving 5-30% used in the silicon brick body from constant temperature to 1700°C, and then down to normal temperature, the coating the silicon brick like iron net tied, the silicon brick does not crack, no damage, solve the problem that must be insulated below 1000°, prolong the service life of the furnace 1-3 times; With good insulation performance and film insulation resistance ≥120MQ, the heating furnace with electricity as energy does not leak electricity, which ensures the safe production of operators. Safe to use, no pollution, no harm, acid and alkali resistance, boiling, soaking and high insulation energy-saving features.

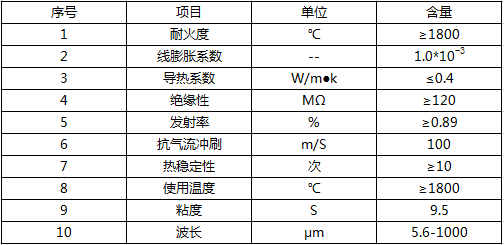

3. Technical indicators